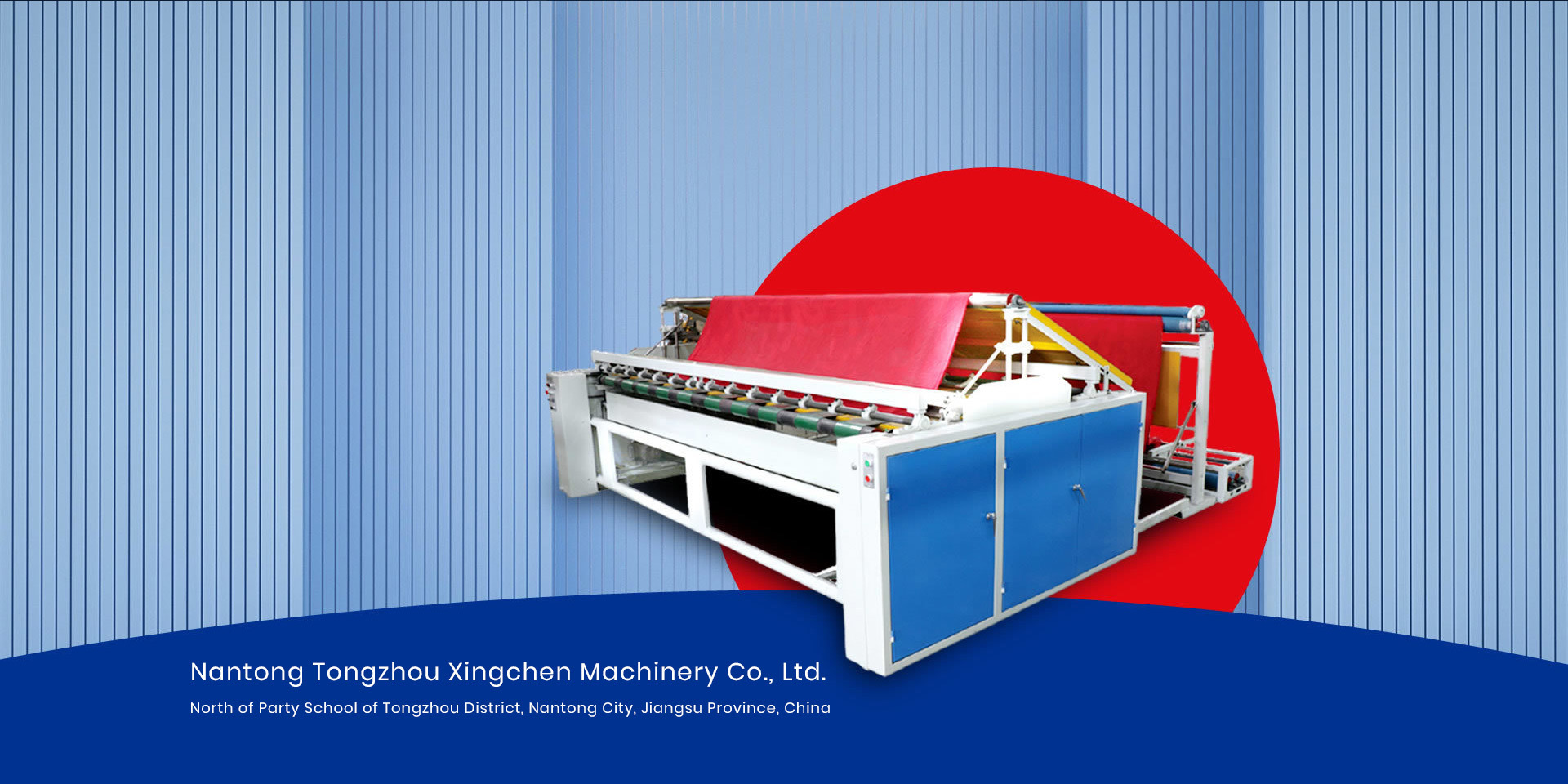

Hot Products

Customer satisfaction is the foothold of providing products and services; win-win development is the prospect and future of enterprise cooperation!

Years of experience in printing and dyeing textile industry

Nantong Tongzhou Xingchen Machinery Co., Ltd., formerly known as Tongzhou Jinsha Power Machinery Factory. Founded in 1987, it is located in the north head of the Party School of Tongzhou District, Nantong City, Jiangsu Province. In 1998, it was restructured from a municipal collective to a private enterprise.

01

Complete technical solutions

The "Jingri" trademark has been successfully registered in the State Trademark Administration, and has a number of independent intellectual property rights of the code cloth machine technology patents, the company strictly in accordance with enterprise standards to organize production, has passed the ISO9001 quality system certification.

02

Whole Process Control of Product Quality

Xingchen people pursue the business philosophy of "excellent, efficient, high-quality, and sincere", with strong equipment strength, rigorous scientific management, superb production technology, tenacious work style, and enthusiasm to provide customers with sincere and professional services!

03

Advanced production and processing equipment

The company now has a complete range of mechanical processing equipment: large boring machine, gantry milling, cylindrical grinding machine, surface grinding machine, CNC milling machine, CNC lathe, forging equipment, etc. a total of more than 60 sets.

04

About Xing Chen

Xingchen Machinery-Creating Value for Customers

Nantong Tongzhou Xingchen Machinery Co., Ltd. was founded in 1987 and restructured from a municipal collective to a private enterprise in 1998. It is located at 128 Tongjue Road, Tongzhou District, Nantong, Jiangsu, China. Our company has a number of independent intellectual property rights of cloth plaiting machine technology patents, and the registered trademark "Jingri". Our company organizes production in strict accordance with enterprise standard, and has passed ISO9001 quality management system certification.

Currently, our company has two plants, covering an area of nearly about 20,000 m2 and a building area of over 6,000 ㎡.

Currently, our company has more than 40 sets of machining equipment, including laser cutting machines, large boring machines, gantry milling machines, cylindrical grinding machines, CNC milling machines, CNC lathes.

......

Founded

Site Area

Building Area

Machining Equipment

Application Case

Customer satisfaction is the foothold of providing products and services; win-win development is the prospect and future of enterprise cooperation!

Customer Case

Customer Case

Customer Case

Customer Case

Customer Case

News dynamics

Customer satisfaction is the foothold of providing products and services; win-win development is the prospect and future of enterprise cooperation!

2024/04/19

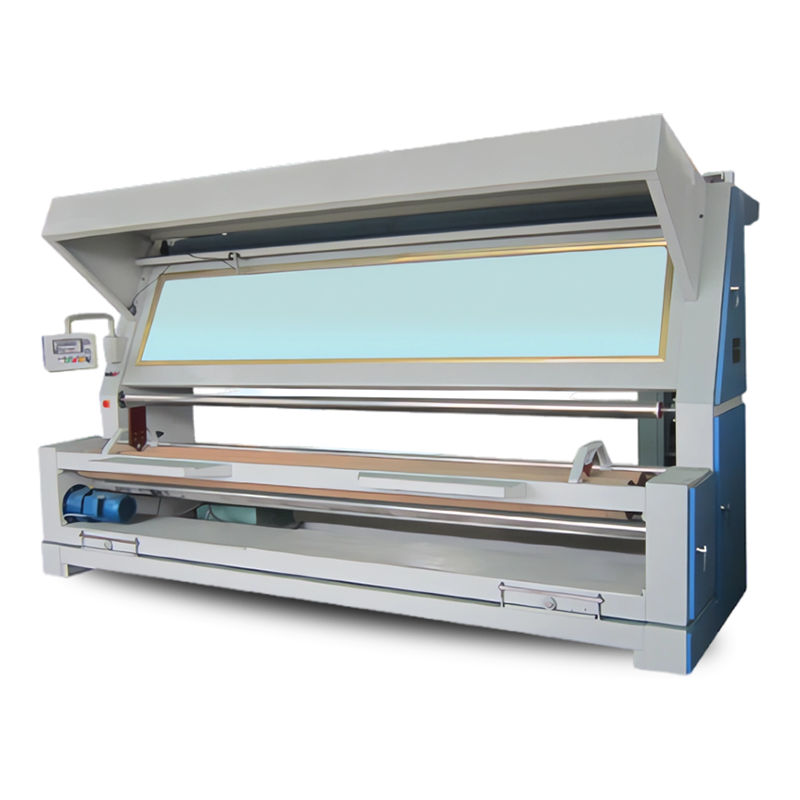

What is the working principle of an automatic fabric inspection and rolling machine?

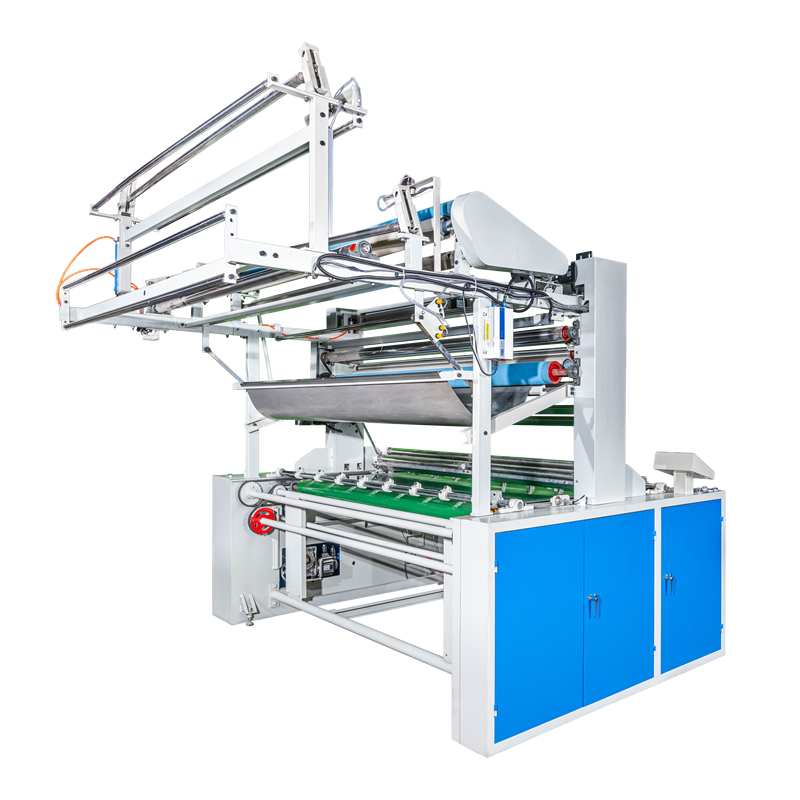

The automatic fabric inspection and rolling machine is a highly automated device that can automatically complete the tasks of fabric inspection and rolling. This equipment uses advanced photoelectric detection technology, capable of quickly and accurately detecting the quality and defects of the fabric and classifying them. At the same time, the automatic fabric inspection and rolling machine is also equipped with an automatic rolling mechanism, which can automatically roll up the inspected fabric, reducing manual operations and improving efficiency.

2024/04/18

How to choose different types of roll fabric machines?

In order to improve production efficiency and reduce labor costs, the clothing factory can selectively choose different types of roll fabric machines based on the characteristics of the products to achieve the best results. The automatic edge-alignment roll fabric machine is equipped with electric eyes for alignment during winding, ensuring reliable product quality and facilitating operations before cutting the bundles. It is suitable for winding high-density and heavy fabrics, especially for the production of small batches of various types of fabrics, where the benefits are even more apparent.

2024/04/17

What is the significance of using an automatic fabric cutting machine?

In the increasingly competitive apparel and textile industry, how to take the lead and surpass competitors has become a major issue for enterprises, especially how to break through the fierce market competition. It is particularly important to systematically control the quality, cost, and efficiency of finished products.

2024/04/15

What fabrics are suitable for large roll fabric machines?

As we all know, different products are suitable for different machines. Which fabrics are suitable for large roll fabric machines? The fabrics suitable for large roll fabric machines mainly include: ordinary fabric, non-woven fabric, foam fabric, acetate fabric, conductive fabric, etc. However, the characteristics of these fabrics are also different, so the operating speeds of the machines will vary. For example, when rolling up foam fabric, the large roll fabric machine must operate at a slower speed because foam fabric is very prone to breaking. Familiarity with the characteristics of each type of fabric is also very helpful for using the machines.